AirTec Revolution vs. Big Oil

Technology: The missing component

Did you ever notice how fast the world is changing? 30 years ago no one knew the word “cell phone,” computers were slow and rare, and a big screen T.V was the weight of a smart car. Yes, the world has come along way, however, when you think about it nearly all of the advancements in the last 30 years have been in the electronics industry. GPS, self-driving cars, and most recently in the news artificial intelligence–All electronically based technologies. So what about other industries—Has Lubrication Technology come as far as it can? Why have the biggest advancements in the Oil Industry been focused on refining technology? What is beyond petroleum-based lubricants?

Micro-Ceramic Oil

One of the cornerstones of the AirTec Revolution is Micro-Ceramic Oil by Wagner/AirTec. Micro-Ceramic Oil is a highly specialized product that can be used in engines, gearboxes, and drives. Unlike standard lubricants, micro-ceramic oil bonds and adheres to the surfaces of the engine or gearbox and greatly reduces friction which results in better fuel mileage and less engine wear.

How Micro-Ceramic oil works

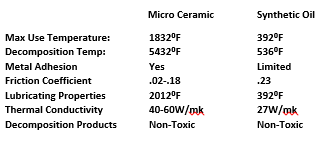

All metal, even highly polished metal, is porous as shown in the illustration above. Normal mineral oil and synthetic oils will flow onto these surfaces, but under high stress, pressure, or temperature they are displaced and small amounts of metal on metal contact occur, causing wear and increased friction. However, with a micro-ceramic oil additive, the micro-ceramic particles fill and adhere into the pores on the metal surfaces creating a much smoother surface which reduces friction and wear. Even more impressive is the fact that micro-ceramic particles stay adhered to the metal surfaces even when the oil is not circulating, so startup/cold start wear is greatly reduced! Let us see how Wagner and AirTec Micro Ceramic Oil compare to a top line full synthetic:

AirTec Micro Ceramic Oil by Wagner Spezialschmierstoffe is truly revolutionizing the world of lubrication.