How do you CORRECTLY load a grease gun???? Greasing is a necessary part of machine maintenance from a lawn mower, to a tractor, or a bulldozer all machines need grease to live. Greasing can be a hard, messy, frustrating job—unless you know how to properly use a grease gun and load a grease gun. Here is a step by step guide to help you stay clean during this process.

Identify the type of grease gun you have: Is it a standard or Lube-Shuttle® greasing system? There are many differences between standard and lube-shuttle® greasing systems and it is important to know them before buying grease, a grease gun, or changing a tube.

Here is a video to help you identify the greasing system you are using

Once you have identified the greasing system you are using select the right set off instructions and proceed to follow the instructions step by step.

Steps for loading a Standard Grease Gun.

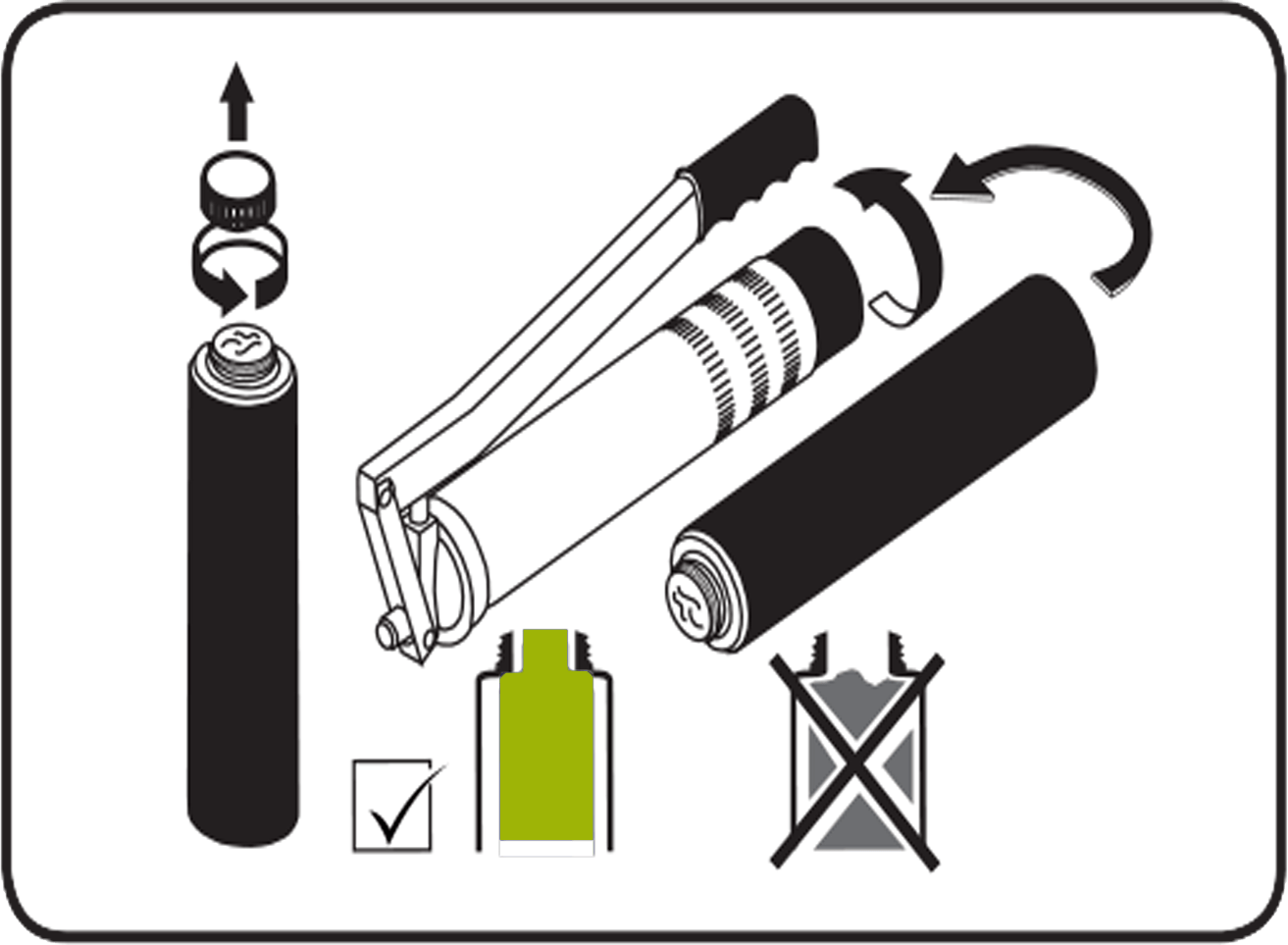

- Pull the handle at the rear of the grease gun to pull the plunger to the back of the canister. Lock the handle all the way back so the spring is fully compressed, and the plunger is at the rear of the canister. The handle can be locked in a few different ways depending on the type of grease gun, many have a secondary notch or small lever to lock the handle and spring assembly back.

- Unthread the grease gun canister from the head of the grease gun.

- Using your fingers (wear gloves) or with a pliers remove the old tube of grease from the grease gun canister and properly dispose of the used tube in accordance with local regulations.

- Before inserting the new grease tube remove the plastic end cap. Be sure to only remove the end cap not the foil side or plastic pull ring.

- Once the plastic cap is removed insert the grease tube into the grease gun canister. The end of the tube where you just removed plastic cap goes into the canister first.

- Once the grease tube is fully in the grease gun canister the top of the grease tube should be even with the top of the grease gun canister. Once this is confirmed, remove the foil or plastic seal by pulling on the ring at the top of the grease tube.

- Once the seal has been removed thread the grease gun canister back on the grease gun head.

- If the grease has a bleeder or value open it.

- Once the bleeder or value is open release the plunger and press the handle at the base of the grease gun fully back into the grease gun canister.

- Pump the grease gun handle like you are greasing a fitting. Once the grease starts to come then close the bleeder or valve.

- If necessary, repeat steps 8 through 10 to remove all the air from the grease gun head.

Common Problems that can arise

Standard style grease guns can be problematic, here are a list of issues that may arise and how to solve them.

- Air Gaps/Loss of Prime. Work the bleeder valve and pump the handle to try and remove any air left in the grease gun head. If you believe the bleeder valve is not functioning correct you may have to loosen the grease gun head from the canister holding the grease. BE SURE TO NOT UNTHREAD COMPELTELY AS GREASE WILL FREE COME OUT OF THE CANISTER CAUSING A MESS!!!

- Grease leaking from the grease gun. Unfortunately this is a continuing problem with standard grease guns, the only remedy is to try a different grease, place the grease gun in a bag with a towel, or invest in a lube-shuttle® grease gun system.

Steps for Lube-Shuttle® Grease Gun System

- Unthread the empty cartridge from the grease gun, if the grease gun is new simply move to step

- Unscrew the black cap from the grease tube

- Press on the follower plate of the grease tube until ¼ to ½ inch of grease is sticking out of threaded end of the cartridge.

- Thread the grease tube into the grease gun.

- Pump the grease gun handle.

- If the grease gun does not start to pump grease with in 10 strokes remove the tube and repeat steps 3 through 5. If any issues continue press more grease up form the end of the cartridge prior to threading in the cartridge.

Issues that may arise:

Grease not pumping evening, feels like air may be in the grease gun head.

- Solution: Remove the tube of grease from the grease gun, press approximately 3/8inch of grease up from the head of the tube, and re-thread the tube in the grease gun. This should press any air in the grease gun head out.